Application Scenario Solutions

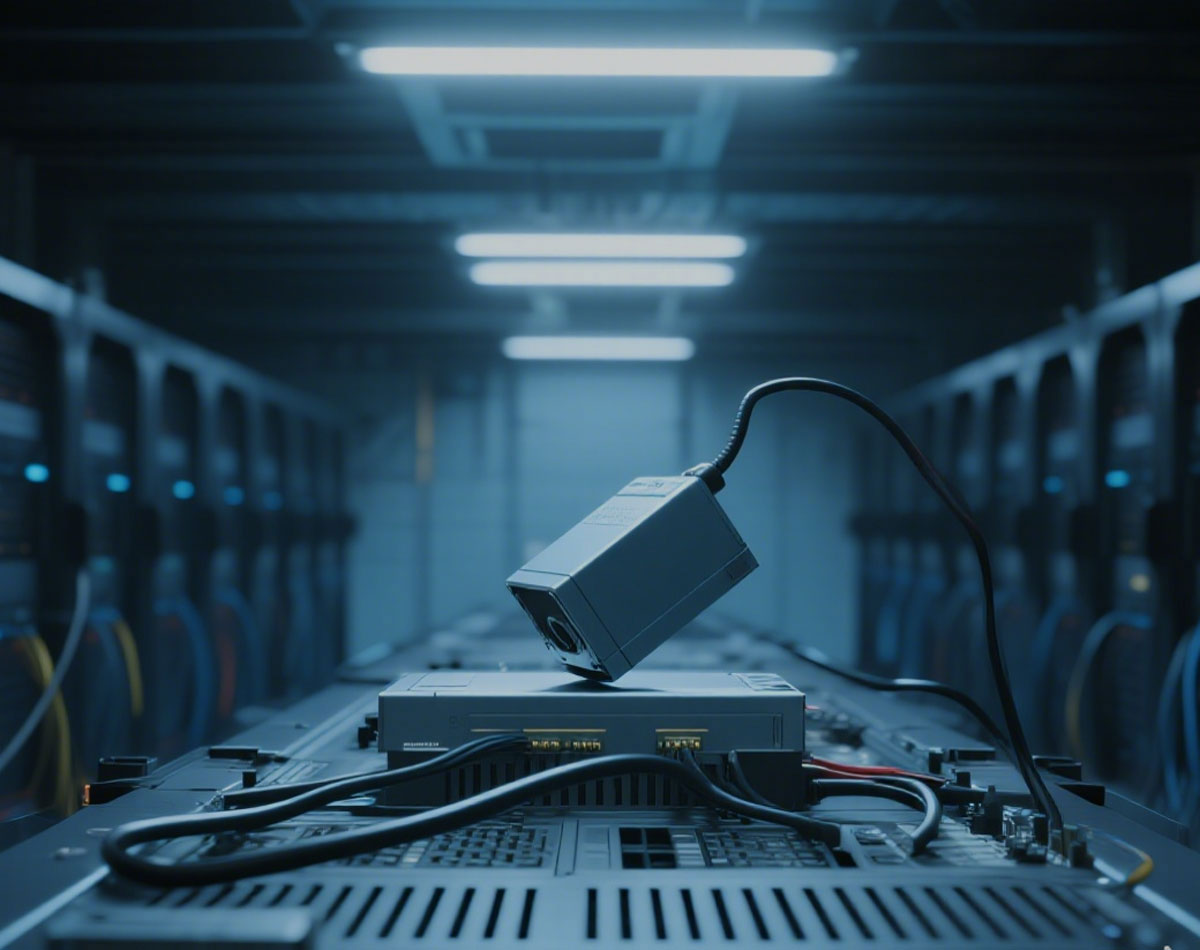

The unique feature of CRPS lies in its highly responsive adaptation to load variations, enabling rapid adjustment of current output while maintaining stable voltage and frequency. This optimizes control logic and enhances host management efficiency.

Its high reliability, efficiency, and stability make it an ideal choice for enterprise-level applications, cloud computing, and storage solutions—particularly in scenarios demanding exceptional power requirements and stability.

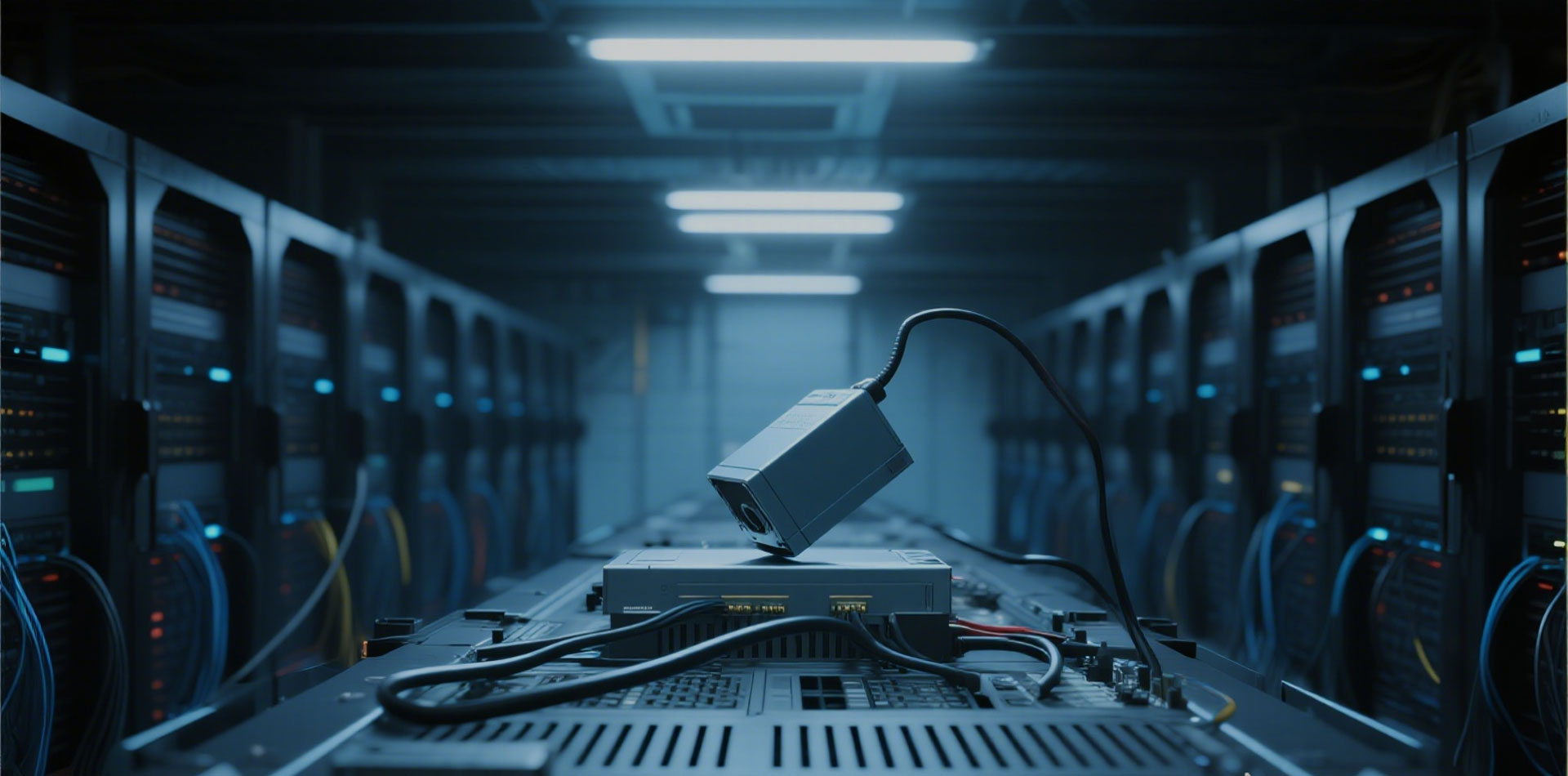

System Architecture Diagram

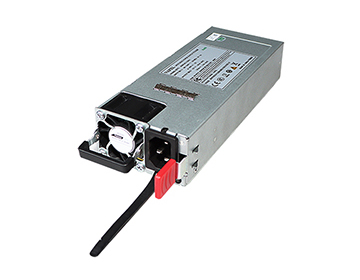

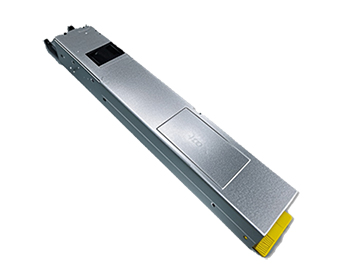

CRPS power supplies, fully known as Computer Redundant Power Supplies, are high-end power solutions specifically designed for commercial servers. They consist of a primary power supply and a redundant backup power supply, ensuring continuous server operation even if the primary power supply fails. Their significant advantage lies in their ability to adapt to rapidly changing load demands while delivering highly efficient power delivery. CRPS power supplies typically feature hot-swap capability, allowing power modules to be replaced or installed without interrupting server operation. The primary and backup power supplies share the load; when the primary power supply fails, the backup power supply immediately takes over, preventing forced shutdown of the host system.

CRPS power supplies typically feature hot-swap capability, allowing power modules to be replaced or installed without interrupting server operation. The primary and backup power supplies share the load; when the primary fails, the backup immediately takes over, preventing forced shutdowns. This provides robust power protection for servers, effectively addressing power supply instability and ensuring stable system operation.

Innovative R&D

Smart Manufacturing

Monthly production capacity of 1 million units, process first-pass yield >99.8%, market return rate ≤200PPM; refined PCB processes, SMT solder joint DPPM below 40ppm; advanced reflow soldering needle technology ensuring superior soldering quality,

High production efficiency; patented core reflow oven curing technology enables streamlined operations; comprehensive production equipment ensures efficiency and product consistency; fully automated testing systems effectively reduce market DPPM;

In-house developed electronic feedback load and real-time aging monitoring systems; process integration during design phase enhances product manufacturability; small-batch production validation ensures overall product first-pass yield.