Application Scenario Solutions

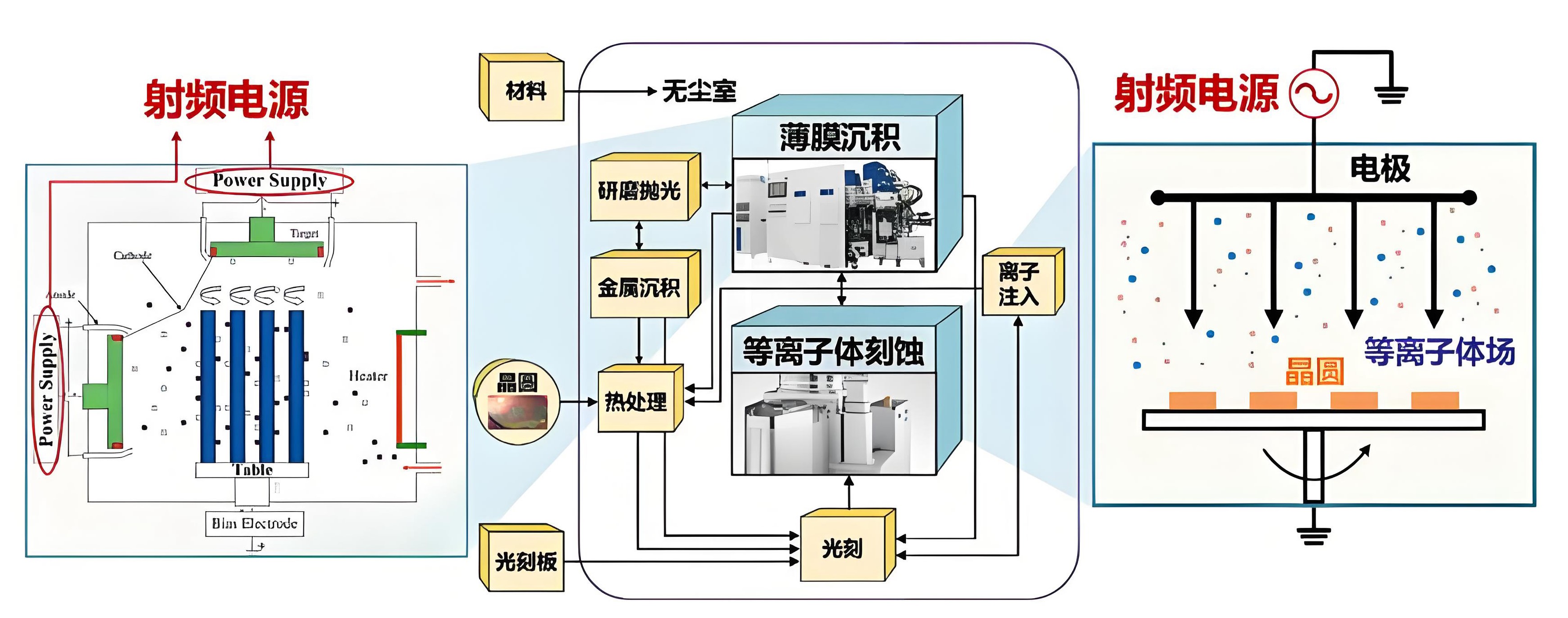

Application Scenarios of RF Power Supplies in Semiconductor Manufacturing

1. Plasma Etching

Plasma etching, a common technique in semiconductor processes, requires generating plasma through gas discharge to etch semiconductor materials. RF power supplies play a critical role in this process. By regulating the plasma's energy and density, they enable high-precision, high-efficiency semiconductor etching.

2. Physical Vapor Deposition

Physical Vapor Deposition (PVD) is a widely used technique in semiconductor manufacturing. It utilizes a high-frequency field within a reaction chamber to ionize atoms of metal or semiconductor materials, forming plasma. Substances are then deposited onto substrates through physical interactions. RF power supplies provide the necessary high-frequency electric fields, driving the advancement of PVD technology.

3. Ion Implantation

Ion implantation is a common technique in semiconductor manufacturing that replaces certain impurities within a material with other elements to alter its electrical properties. RF power supplies deliver electrical energy during ion implantation, accelerating ions and injecting them into the semiconductor material.

System Architecture Diagram

An RF power supply is a device that converts AC power into high-frequency electrical energy, typically operating at frequencies between 1 and 100 MHz. In the semiconductor industry, RF power supplies are widely used in semiconductor manufacturing processes, primarily to provide the high-frequency electrical energy required by semiconductor equipment.

An RF power supply primarily consists of three key components: the RF source, the isolator, and the power amplifier. The RF source generates high-frequency signals within the 1–100 MHz range. The isolator separates the high-frequency signal from the RF source, while the power amplifier amplifies the signal's power to the level required by semiconductor equipment.

With the continuous advancement of semiconductor technology, the application of RF power supplies in the semiconductor field will become increasingly widespread. Leveraging their advantages of high precision, high efficiency, and reliability, RF power supplies play a vital role in semiconductor processes, making significant contributions to semiconductor manufacturing and development.

Innovative R&D

Over 700 R&D engineers, with more than 80% holding bachelor's degrees or higher. Over 5,000 proven case studies, More than 300 patented technologies, Over 200 classic circuit designs and methodologies. Verification & Certification Testing: Safety Testing Lab, EMC Lab, HALT/HASS Lab, PLD Lab, Lightning Strike Lab, Air Tightness Lab, Environmental Lab, ROHS Lab, Salt Spray Lab, Mechanical Lab

Smart Manufacturing

Monthly production capacity of 1 million units, process yield rate >99.8%, market return rate ≤200PPM; comprehensive PCB processes, SMT solder joint DPPM below 40ppm; advanced reflow soldering needle technology ensures superior soldering quality and high production efficiency;

Patented core reflow oven curing technology enables streamlined operations; comprehensive production equipment ensures efficiency and product consistency; fully automated testing systems effectively reduce market DPPM;

In-house developed electronic feedback load and real-time aging monitoring systems; process integration during design phase enhances product manufacturability; small-batch production validation ensures overall first-pass yield.