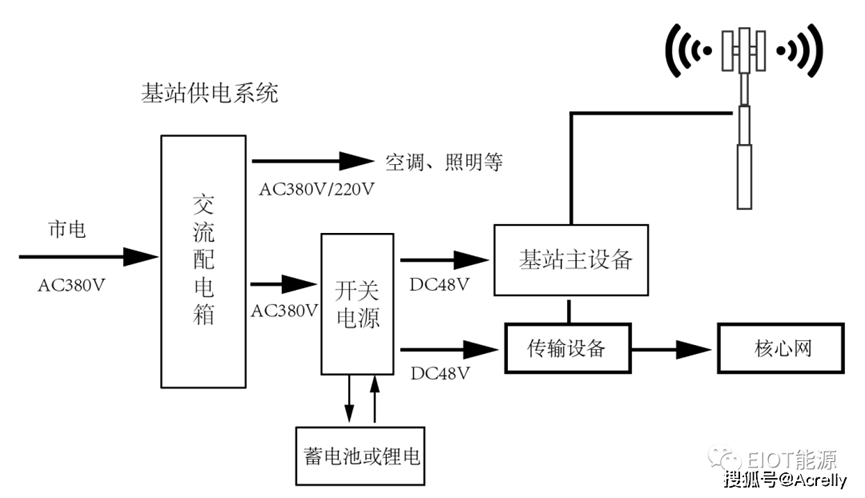

Application Scenario Solutions

Communication power supplies are critical infrastructure for telecommunications networks, primarily providing uninterrupted power to communication equipment. Understanding telecom operators' power solutions and assisting them in designing optimal power solutions will be vital for the advancement of power technology. Application scenarios span base stations, data centers, and new energy communication domains.

System Architecture Diagram

The development of communication power supply technology has progressed through linear power supplies and high-frequency switching power supplies, and is now evolving toward high efficiency and intelligence. The Technical Specifications for Parallel Communication Power Supply Systems for Power Applications, led by State Grid Corporation of China, has pioneered the implementation of online replacement of parallel components and automatic capacity verification functions, advancing the industry's standardization process.

Innovative R&D

Smart Manufacturing

Monthly production capacity of 1 million units, process first-pass yield >99.8%, market return rate ≤200PPM; refined PCB processes with SMT solder joint DPPM below 40ppm; advanced reflow soldering needle technology delivering superior weld quality and high production efficiency;

Patented core reflow oven curing technology enables streamlined operations; comprehensive production equipment ensures efficiency and product consistency; fully automated testing systems effectively reduce market DPPM;

In-house developed electronic feedback load and real-time aging monitoring systems; process integration during design phase enhances product manufacturability; small-batch production validation ensures overall first-pass yield.