Application Scenario Solutions

“Low-altitude economy,” as a prime example of new-quality productive forces, was included in the government work report for the first time, signaling the gradual emergence of a brand-new trillion-yuan market. Riding the wave of this booming sector, the drone industry is taking off.

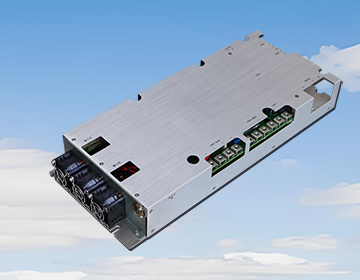

Nueda Zhongyuantong is empowering the low-altitude economy by introducing products such as power supplies for crop protection drones, stream drones, electric vertical takeoff and landing (eVTOL) aircraft, fuel cell drones, and modular drone power supplies.

These solutions are widely applied across the low-altitude economy, including drones (multi-rotor, fixed-wing, hybrid-wing, helicopters) and eVTOL aircraft!

System Architecture Diagram

In March 2024, the Ministry of Industry and Information Technology (MIIT) and three other departments jointly issued the “General Aviation Equipment Innovation and Application Pilot Program (2024-2030).” The program outlines that by 2027, China's general aviation equipment supply capacity and industrial innovation capabilities will be significantly enhanced. New general aviation equipment characterized by unmanned, electric, and intelligent technologies will achieve commercial application in urban air transport, logistics distribution, emergency rescue, and other fields.

Innovative R&D

Smart Manufacturing

Monthly production capacity of 1 million units, process first-pass yield >99.8%, market return rate ≤200PPM; refined PCB processes with SMT solder joint DPPM below 40ppm; advanced reflow soldering needle technology delivering superior weld quality and high production efficiency;

Patented core reflow oven curing technology enables streamlined operations; comprehensive production equipment ensures efficiency and product consistency; fully automated testing systems effectively reduce market DPPM;

In-house developed electronic feedback load and real-time aging monitoring systems; process integration during design phase enhances product manufacturability; small-batch production validation ensures overall first-pass yield.